Industrial Water and Wastewater Treatment.

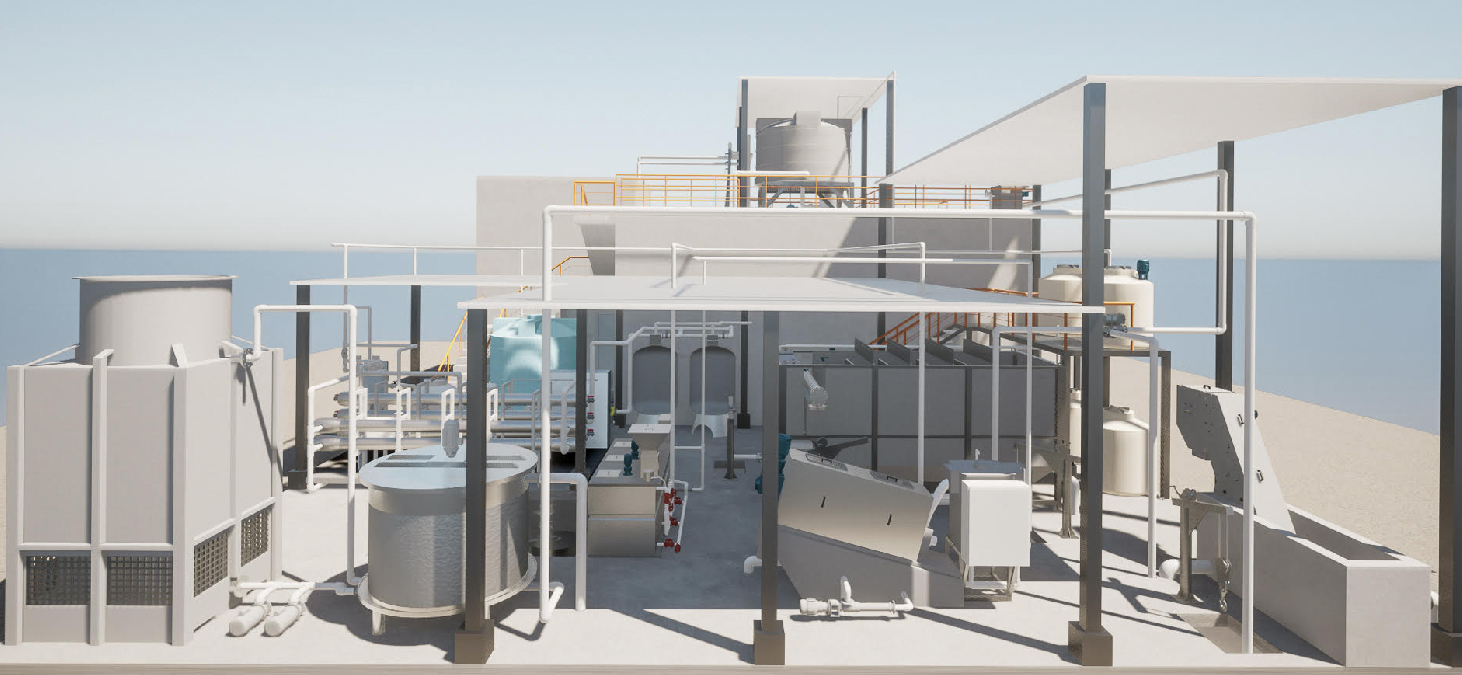

MBR treatment modules for wastewater.

We are a company specialized in the design and construction of sustainable projects related to water and sanitation.

We identify our clients' needs and, based on that, propose the most optimal solution using engineering, innovation, and cutting-edge technology.

- 1. Pinsa Mazatlán

First industrial MBR plant in the world, installed in 2002 - 2. Maz Industrial Mazatlán

Fishmeal plant with a complete MBR system and advanced oxidation, reuse installed in 2003 - 3. Sardinas de Sonora Guaymas

Fishmeal plant with a complete MBR system, advanced oxidation, and sludge dewatering - 4. MARS EFFEM Querétaro

Pet food processing plant with a complete MBR system, tertiary oxidation, and Volute, installed in 2008 - 5. MARS EFFEM Querétaro and Poncitlán

UF system for fluoride and ammonium nitrogen removal, installed in 2009 - 6. Pilot Plant Los Laureles Guadalajara

MBR system, evaporation, and tertiary treatment, installed in 2010 - 7. Tequila El Viejito / Patron Spirits

Vinasse treatment with advanced oxidation and reverse osmosis, installed in 2012 - 8. CIP Ozone System Pyrat Rum Agunila

Installed in 2013 - 9. Femsa

CIP system with ozone for simultaneous sanitization of 4 lines, installed in 2004 - 10. MBR Plant Baja Marine Foods

MBR system, cooling, tertiary treatment, and Volute with telemetry, installed in 2023 - 11. MBR Plant Puratos Mexico, Chile, and Brazil

Installed in 2022 and 2024 - 12. Citrex Martínez de la Torre Plant

Primary system and sludge treatment, installed in 2020 - 13. Xtra Congelados León Guanajuato

MBR system, Volute, and advanced oxidation tertiary treatment, installed in 2019 - 14. Frexport Zamora Michoacán

MBR system, Volute, and advanced oxidation tertiary treatment, installed in 2020 - 15. Xsant Toluca Edo Mexico

MBR plant, Volute, and tertiary oxidation system, installed in 2019

Municipal and Industrial

The combination of microfiltration/ultrafiltration membranes with the activated sludge process offers significant advantages compared to traditional wastewater treatment methods...

At approximately 0.5 bar, water passes through the membrane walls. Cleaning is performed through the aeration flow...

+ MBR System Advantages / PDF

Clean In Place

One of the biggest challenges for food processing and bottling companies is the cleaning and sanitization of their process equipment, such as work tables, kettles, tanks, pipes, and all processing areas.

Currently, a large number of chemicals are used that pollute the environment and require special handling for storage, application, and disposal.

Cleaning times and dosages vary depending on the area to be cleaned, but the loss of processing time and the investment in chemical products are highly significant. Ozone systems reduce cleaning times by up to 70% and chemical and steam expenses by up to 90%.

Odor Control

One of the biggest issues in lift stations or treatment plants is the generation of unpleasant odors, mainly caused by hydrogen sulfide.

Ozone, in odor control systems known as exhaustive treatment, has been highly successful for many years. The basic principle is the addition of ozone into air ducts that contain odor-causing components.

Another common application of ozone is in casinos or bars, where it is installed in air injection ducts, achieving total odor elimination and increasing the amount of O₂ in the environment.

Atmospheric Evaporators

The atmospheric evaporator is a system designed to artificially replicate all the factors of natural evaporation through forced evaporation, optimizing contact times and manipulating natural factors that limit evaporation.

It is used in the treatment of complex or produced water systems, becoming the most cost-effective system in terms of investment and cost per m³ treated.

It is applied in power generation plants, thermoelectric plants, leachate treatment, reverse osmosis reject water treatment, excess water treatment in mines, and produced water treatment, among others.

Clean In Place

One of the biggest challenges for food processing and bottling companies is the cleaning and sanitization of their process equipment, such as work tables, kettles, tanks, pipes, and all processing areas.

Currently, a large number of chemicals are used that pollute the environment and require special handling for storage, application, and disposal.

Cleaning times and dosages vary depending on the area to be cleaned, but the loss of processing time and the investment in chemical products are highly significant. Ozone systems reduce cleaning times by up to 70% and chemical and steam expenses by up to 90%.

Odor Control

One of the biggest issues in lift stations or treatment plants is the generation of unpleasant odors, mainly caused by hydrogen sulfide.

Ozone, in odor control systems known as exhaustive treatment, has been highly successful for many years. The basic principle is the addition of ozone into air ducts that contain odor-causing components.

Another common application of ozone is in casinos or bars, where it is installed in air injection ducts, achieving total odor elimination and increasing the amount of O₂ in the environment.